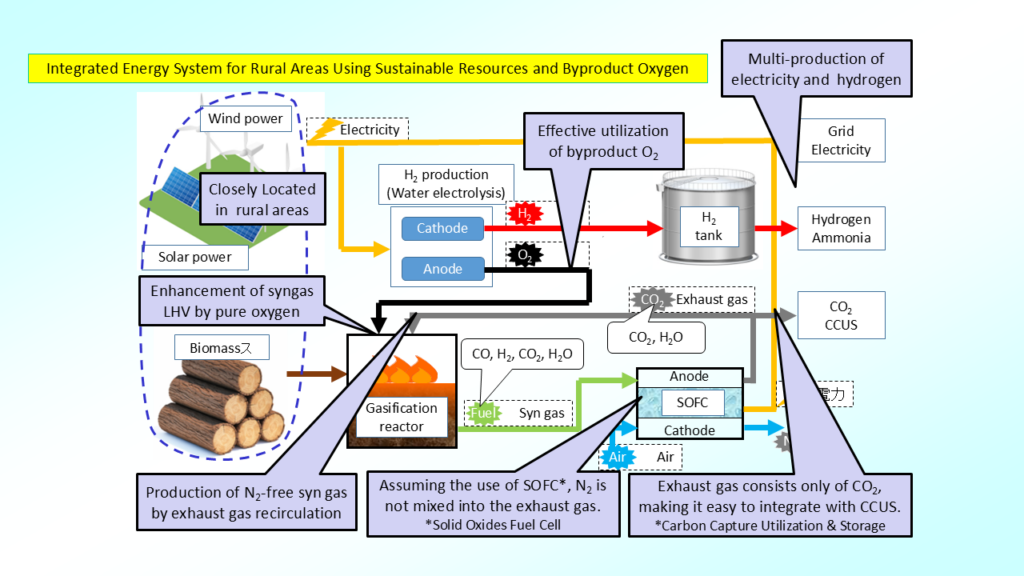

Concept

The goal of the research is to establish a small-scale, high-efficiency integrated energy system for rural areas where wind, solar, and biomass resources are closely located. This is achieved by effectively utilizing by-product oxygen from renewable energy-based hydrogen production plants to create oxygen-enriched conditions for biomass gasification processes. It also enables the separation and capture of carbon dioxide to realize BECCS (Bio-Energy with Carbon Capture and Storage). The study envisions on-site treatment of low-calorific-value biomass resources, which are typically challenging to utilize in conventional biomass gasification. Specifically, the system involves a recirculating flue gas oxy-biomass gasification reactor with a thermal input of less than several tens of kW, integrated with solid oxide fuel cells (SOFC) for power generation.

CO2 concentration dependency in CO2 gasification behavior of woody biomass

The main components of combustion flue gas are H2O and CO2, both of which exhibit reactivity as gasifying agents in the high-temperature zone of a biomass gasification reactor (C + H2O → CO + H2, C + CO2 → 2CO). This study focuses on the CO2 concentration dependency to explore conditions that enhance the calorific value of the produced gas.

Improvement of carbon conversion efficiency of woody biomass under oxygen-enriched conditions

Biomass gasification reactions require a heat source, typically provided by partial combustion conditions. This study aims to identify operating conditions that simultaneously maintain reactor temperature and produce high-calorific-value syngas under partial combustion conditions using oxygen-enriched flue gas.

The power generation characteristics of solid oxide fuel cells (SOFCs) using syngas from biomass gasification

Syngas from biomass gasification contains not only H2 but also CO, CO2, and small amounts of hydrocarbons. This study investigates the effects of these components on the fuel electrode of SOFC and focuses on developing technologies such as catalyst designs resistant to degradation during internal reforming and control techniques for the microstructure of fuel electrodes.